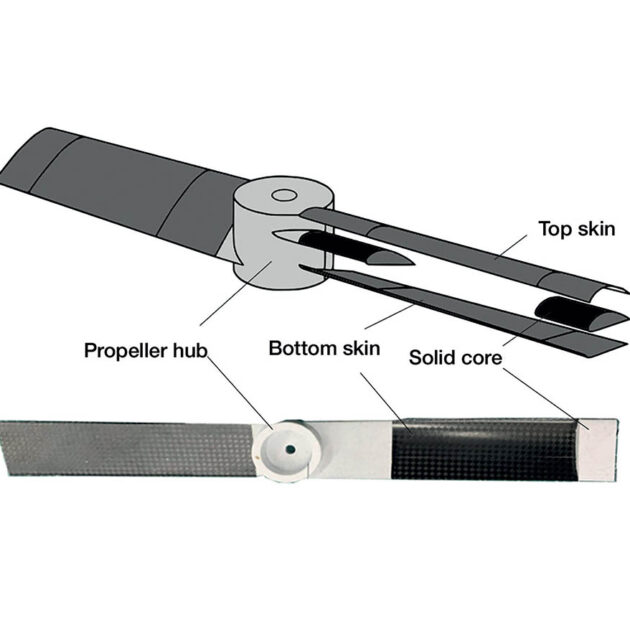

Diagram of rapid actuator-less deployable drone blade

With folded blades, a drone fits in tight places. Picture a cylinder 15 cm (6 in) wide and 1 m (3 ft) long – about the size of 3 paper towel rolls stacked longwise. Imagine a soldier carrying a cannister this size like a backpack, a drone nested inside. When the command comes, the soldier launches the drone, and the blades have 2 seconds to unfold and reconfigure.

However, there is a mission-critical obstacle: the mechanical actuators struggle to power this spontaneous transformation.

Purdue University’s actuator-less deployment drone blade

Purdue University’s Composites Manufacturing and Simulation Center (CMSC) is developing an actuator-less deployment drone blade. The concept has been proven in simulations and static experiments. The next R&D phase begins soon, with testing in a new wind tunnel built expressly for this purpose.

Leading the project is Kawai Kwok, Ph.D., Purdue associate professor, School of Aeronautics and Astronautics, and leader of Purdue’s Aerospace Structures Design Lab. “The design will be challenging, but if we can change our thinking about static structures for aerospace applications and consider dynamic deployable and reconfigurable structures, there will be many benefits,” he said.

330 million years of actuator-less flights

Purdue’s inspiration comes from earth’s first in flight: the humble insect. Winged insects date back 330 million years to the Carboniferous period – named for underground coal deposits originating then. Now, these prehistoric contemporaries reunite for a carbon-fibre composite breakthrough.