Coriolis

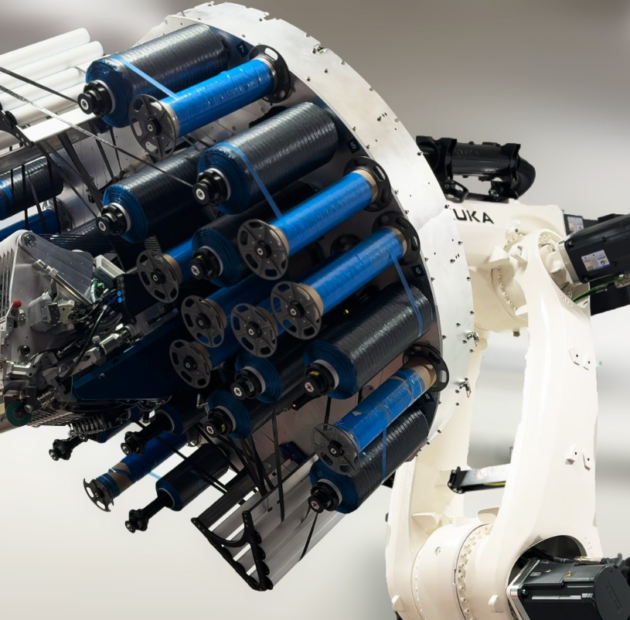

The French specialist in automated fiber placement (AFP) technology Coriolis Composites has launched the C3 dockable AFP head (16 x ½’’ or ¼’’). Development of the C3 head is using proven technologies used on the existing C1.2 and C5 machines. Designed for long-term use, the C3 head is qualified for both current and next generation aerostructures.

” Coriolis is now the only AFP machine supplier capable of addressing all part types from complex geometries (with the C1.2 range) to large components (with the C3 and C5 ranges) with a high level of industrialization.“, says the company in her press release.

It introduces proven technologies:

· Reliability: The feeding/clamping and cutting unit is coming from the C1.2 machine with the 0.25in material tow width with proven track records. This system is now used on the C3 machine with 0.5in material.

· Dockable head: Quick coupling technology to ensure fast and reliable head changes for flexible manufacturing to maximize machine availability – Already validated on Csolo & C5.

· AIS: Compatible with our online Automatic Inspection System

· AFP “Nose” with cutting module: Validated on the C1.2 & C5, the AFP Nose incorporates a robust cutting module, capable of 100,000 cuts per blade. It supports both adding and cutting fiber at a speed of up to 1 m/s by respecting the aerospace accuracy requirements.

· Ergonomic design: Designed for operator comfort and efficiency, the C3 head offers frontal access to all components, allowing maintenance and cleaning operations to be performed without any tools (Level 1 & 2). This intuitive and user-friendly design minimizes downtime and ensures a faster learning for new operators.

· Motorized module for backing film: The re-winding design provides consistent backing film management. It also includes a backing film detection device to guarantee part integrity and enable rapid operator intervention.

· Fiber tension: accurate pressure control of the dancing arm

· Compaction force sensor on the roller: Provides direct measurement as close as possible to the layup, enabling precise compaction control These components have been tested extensively across Coriolis’s earlier machines, ensuring reliability and performance from day one.

Coriolis offers expertise in both low-rail and high-rail gantry systems, providing a comprehensive solution for diverse applications. The C3 represents a significant advancement in dockable AFP head technology, offering manufacturers enhanced flexibility, performance, and ease of use for a wide range of composite part like fuselage sections, wing spars and wing skins, pressure bulkheads and many other kinds of parts.

Lu public network security: 37140202000173

Lu public network security: 37140202000173