Gurit

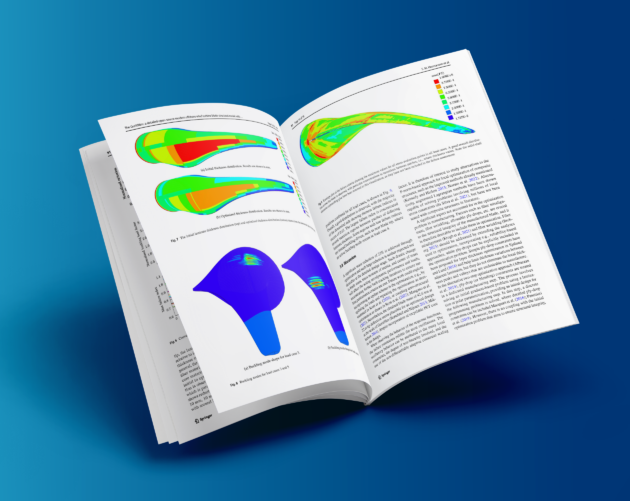

As demand for renewable energy grows, so does the need for more efficient, cost-effective, and sustainable wind turbine technology. Yet, designing and optimising blades remains complex and resource-intensive, Gurit explains. That is why the company developed the Gurit98m in partnership with Aalborg University, a leader in composite structure and wind turbine blade engineering, which aims to simplify the process. The Gurit98m model is publicly available so that engineers, researchers and manufacturers can use it and carry out structural optimisation.

The Gurit98m model has been optimised for performance, its key structural drivers being handled efficiently. It has also been designed so as to reduce the manufacturing costs. At last, it has been conceived in a sustainable way, with its core now made from recyclable PET instead of the balsa wood used previously.

The Gurit98m enables users to improve sustainability by integrating recyclable materials, streamline offshore wind blade design for better efficiency, and accelerate innovation through open-source collaboration. It’s a valuable tool for those looking to stay ahead in a rapidly evolving renewable energy landscape.

Available in Abaqus and Ansys formats, the Gurit98m has been designed to be easy to integrate into R&D projects. Gurit specifies that it is using it to drive innovation in-house, including enhancements to its OptiCore platform.

Lu public network security: 37140202000173

Lu public network security: 37140202000173