photo: Robert Karkowski from Pixabay

Composites in vehicles to explore the moon

Venturi Space presents Mona Luna, the European lunar rover

Venturi Space unveils Mona Luna, its 100% European-built lunar rover. Designed to support the ambitions of ESA and the French CNES, the vehicle will be built at Venturi Space France’s facility in Toulouse. The ultimate aim is to provide Europe with a lunar-capable rover by 2030. The European Space Agency is supporting Venturi Space’s efforts to design and develop the critical technologies required for a large lunar rover, capable of surviving multiple lunar nights. ESA’s support validates Venturi Space’s approach and highlights its expertise. The project will draw on the experience acquired from the programmes to develop the Flio and Flex rovers under a strategic partnership with US-based company Venturi Astrolab, Inc. Venturi Space is currently designing and building the hyper-deformable wheels that will be fitted to those vehicles, along with the associated electrical systems (in Switzerland) and high-performance batteries (in Monaco). The peripheral layers of the wheels include metallic materials, hyper-elastic polymers and composites. The latter are made up of proprietary thermosetting resins and a combination of hundreds of millions of reinforcing fibres.

US Defense chooses Firefly Aerospace for responsive space mission

Firefly Aerospace, leader in end-to-end responsive space services, announced it was awarded a contract to perform a responsive on-orbit mission with its Elytra spacecraft in support of the US Department of Defense’s (DoD) Defense Innovation Unit (DIU) Sinequone Project. During the mission, Elytra will serve as a space manoeuvre vehicle to perform a series of responsive on-orbit tasks, including space domain awareness operations in Low Earth Orbit (LEO). The mission is set to launch as early as 2027. As part of the mission, Elytra will host a suite of government payloads, including optical, visible and infrared cameras, a responsive navigation unit and a universal electrical bus with a payload interface module. Firefly’s Elytra Dawn configuration will utilise common components from the company’s launch vehicles and lunar landers, including the avionics, composite structures and propulsion systems, to enable on-demand mobility, plane changes and manoeuvres with high delta-V capabilities and reliability. Elytra’s main engine, called Spectre, was recently flight-proven on Firefly’s Blue Ghost lunar lander as the reaction control system thrusters that successfully performed Firefly’s final descent on the Moon in March.

Composites used on or around the moon

AnalySwift receives NASA STTR contract to transform spacecraft infrastructure for secondary uses during long-duration missions

AnalySwift LLC, a Purdue University-affiliated company, has received a Phase I STTR (Small Business Technology Transfer) contract from NASA worth $156,424. Allan Wood, AnalySwift president and CEO, said the contract will fund two advancements: processes and hardware to disassemble spacecraft components and reassemble them for a secondary use, and software for multiphysics simulation and analysis of the involved thermoplastics. Kawai Kwok, associate professor in Purdue’s School of Aeronautics and Astronautics, is the principal investigator. Wood said long-duration crewed missions to the moon, Mars and beyond require infrastructure, such as trusses, to be constructed sustainably on these surfaces. But there are immense logistical challenges in transporting heavy and large payloads to space. “The AnalySwift project proposes a novel method of disassembling and reassembling thermoplastic composite joints in space,” he said. “Our proposed method enables reconfiguration of truss structures in space, transitioning away from the current one-time use model to a scalable and sustainable approach.” Kwok said spacecraft components could be quickly and easily repurposed into vastly different geometries. “For example, a lunar lander support truss could become a vertical solar array support truss,” he said. “There are other applications, depending on mission needs using the same set of structural elements and innovative multiphysics modelling.”

Max Space utilises Aluula material for space habitat construction

Private space company Max Space premiered their expandable space habitat at the 39th Space Symposium on 9 April 9 2024, citing its use of material from Aluula Composites to reinforce the structure. The habitat is slated to launch with Space X in 2026 and, according to Max Space, is currently able to orbit the moon and ultimately Mars. Max Space plans to create a family of scalable habitats in varying sizes by 2030, potentially creating stadium-sized expandable structures. “Unless we make usable space in space a lot less expensive and much larger, humanity’s future in space will remain limited,” said Max Space co-founder Aaron Kemmer. Aluula’s lightweight material is used as part of a custom laminate that adds strength and durability to the structural elements of the habitat, making it possible to create a large living and working area at a fraction of the weight and transport costs of traditional crew modules. “The laminate used in the habitat has an incredible strength-to-weight ratio with a combination of high resistance polymers, which is ideal for use in applications where weight and safety is critical, like space travel,” said Aluula’s Chief Innovation Officer Richard Myerscough.

Composites made with lunar material

Basalt material could be used to build China’s lunar research base

Sometimes described as “the green industrial material of the 21st century”, basalt fibre sees its potential applications growing in composite materials. Research is still needed to achieve mass production, and China is showing its determination in this direction.

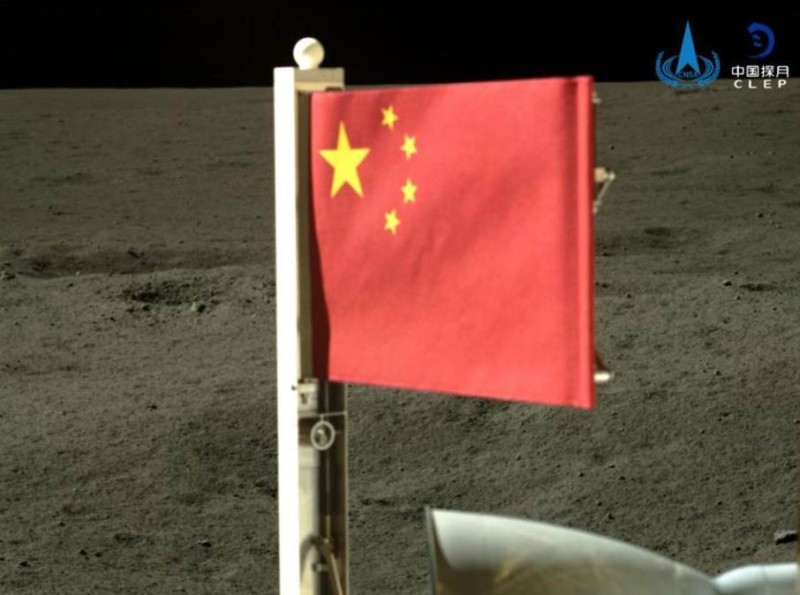

As a sign of China’s presence on the far side of the moon, the Chang’e-6 lunar probe unfurled a Chinese national flag on June 2024 during its sampling mission. The flag was woven from basalt fibre. “We crushed and melted the rocks in order to pull them into thin threads with a diameter about 1/3 that of a hair,” said Professor Zhou Changyi of the National Space Science Center of the Chinese Academy of Sciences. The material could also be used to build China’s lunar research base in the future, Zhou Changyi said to the Chinese media, as the moon has an abundance of this type of rock. “Basalt fibre is lightweight, strong, corrosion-resistant and environmentally friendly with a low carbon footprint. It can withstand temperatures ranging from -269 to 700°C, which further highlights its unique value,” said Liu Jiaqi, an academician of the Chinese Academy of Sciences (CAS) and former director of the CAS Institute of Geology and Geophysics. According to Liu, basalt rocks are abundant in China.

Lu public network security: 37140202000173

Lu public network security: 37140202000173