The process has transformed AM, especially in the composites industry. The SLS printers use high-powered lasers to fuse particles of plastic, metal and composite materials into solid objects, providing unique possibilities for generating complicated shapes, increasing material qualities and reducing manufacturing times. Since it can create parts with intricate geometries and high-performance material qualities, SLS has drawn a lot of interest from sectors like consumer goods, automotive, aerospace and medical. Engineered materials known as composites are created by fusing 2 or more distinct materials to produce a finished product with improved qualities like increased strength, decreased weight and better resistance to corrosion and wear. Composite materials in the SLS 3D printing technique create new opportunities to manufacture sophisticated parts with exceptional mechanical qualities.

The basic idea behind SLS is to use a laser to fuse powdered material into a solid component. Usually, the material is a metal, composite powder or thermoplastic. The powder bed’s surface is scanned by a laser, which uses the geometry from a computerised 3D model to melt or sinter the particles together.

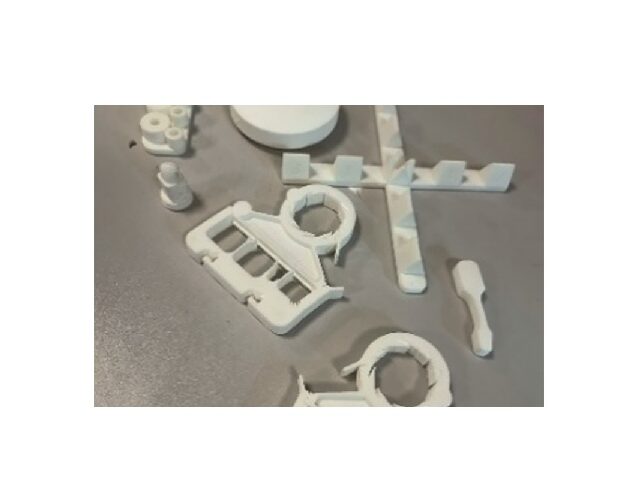

Figure 4: Depowdered 3D printed parts prepared at Butekom

Lu public network security: 37140202000173

Lu public network security: 37140202000173