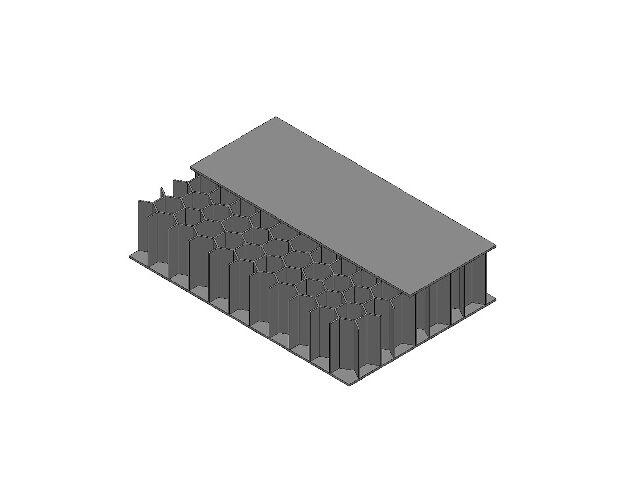

Fig. 1: A sandwich panel with bonded skin and core layers

Composite materials are widely used in industrial sectors, with approximately 2.2 million t produced annually in Europe. In a circular economy, these composite materials are scarce resources that require end-of-life treatment. Recycling of composite waste can extend its useful life and maximise its value. Current efforts in Europe focus on the production of mechanically recyclable thermoplastic composites [2].

One key area of recent advancement in thermoplastic composite production is material extrusion Additive Manufacturing (AM), also known as 3D printing. In this process, short fibre-reinforced thermoplastics are molten and deposited layer by layer in a single step. Regarding environmental effects, AM supports sustainable production via waste reduction, as the components are flexible in design. Furthermore, components can use recyclable or bio-based polymers and composites as feedstock.

Mechanical recycling of thermoplastic composites often degrades the material’s load-bearing properties. Furthermore, sorting and cleaning the components is a tedious process that can contaminate the recycled composite and result in unknown filler type and composition. As a consequence, recycled composites often have a challenging qualification process in the industry.

Joint effort at the Laboratory for Multiscale Mechanics (LM2), a multidisciplinary research facility at the Department of Mechanical Engineering of Polytechnique Montréal, Canada, the project aims to assess the carbon footprint of thermoplastic composites for closed-loop recycling and facilitate the integration of recycled polymers and composites in the industry. The LM2 team is led by 5 professors specialised in additive manufacturing (Daniel Therriault), modelling and simulation, origami/kirigami structures (David Mélançon), smart materials and structures (Sampada Bodkhe), slender structure mechanics (Frédérick Gosselin) and multiscale mechanics (Martin Lévesque). In this project, LM2 works in collaboration with the Poly Circle X.0 laboratory at the Department of Mathematics and Industrial Engineering, founded by Samira Keivanpour and focused on circularity in resources and sustainable engineering.

Targeted use of recycled composites

The team’s proposed solution leverages multimaterial AM to reduce the environmental impact of composites, specifically suggesting the use of Finite Element Analysis (FEA) simulations to identify high-stress and low-stress regions in a component. based on these results, recycled composite materials can be strategically placed in low-stress regions, replacing virgin composites where mechanical performance requirements are less critical. This approach helps reduce the environmental impact associated with the component’s production.

Read more in JEC Composites Magazine n°163!

Lu public network security: 37140202000173

Lu public network security: 37140202000173