picture: Stratview Research

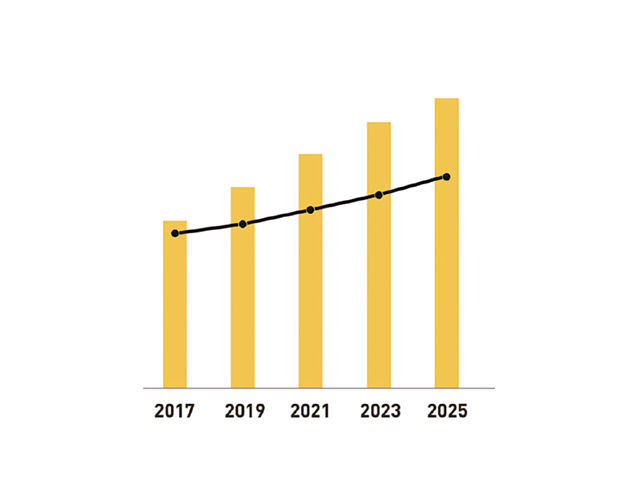

Over the past decade, the number of horizontal wells in the United States has risen from approximately 110,000 to over 200,000 and given the country’s concerted efforts to achieve energy self-sufficiency and its continued reliance on natural gas, such growth in drilling activity is no surprise.

Consequently, the number of fracking operations conducted annually in the US also increased significantly and so has the complexity of the process. Wells have become longer and the stages have multiplied. Notably, the average number of fracture stages per well has increased from roughly 20 in 2015 to as high as 40 as of 2025.

While these technological refinements have enhanced operational efficiency and yield, they have also introduced heightened complexity to well completion and zonal isolation procedures. From an engineering perspective, achieving these levels of intricacy in multi- stage fracturing operations would have otherwise been very difficult for oilfield service companies, if not for the advent of methods like plug-and-perf, the concept of zonal isolation and innovations like frac plugs.

Making well operations more efficient and economical

Originally manufactured from cast iron, frac plugs made their initial transition to composite materials in the late 1980s. This shift was primarily driven by the need to accelerate the drill-out process, as cast iron frac plugs struggled to perform effectively with the increasing perforated lateral lengths in hydraulic fracturing operations. At the time of their introduction, the average lateral length in major shale basins such as the Marcellus and Permian was typically lower than 2,000 ft (609.6 m), which has now extended to over 12,000 ft (3,658 m). Despite the adoption of composite materials, the early versions of composite frac plugs continued to utilise cast iron slips, which still posed operational challenges. Fortunately, these cast iron slips were eventually replaced with ceramic slips, resulting in enhanced performance and efficiency. As a result, drill-out times per plug decreased dramatically – from upwards of 20 min in case of cast iron plugs, to as little as 6-7 min for their composite counterparts in certain instances.

While a reduction of a few minutes per plug may appear marginal in isolation, modern fracturing operations frequently employ anywhere between 60-80 plugs. Even a conservative savings of 10 min per plug aggregates to roughly 13 h, translating into cost reductions of almost US$150,000 (€133,840) per operation.

Lu public network security: 37140202000173

Lu public network security: 37140202000173