Customers can already implement material analysis for the Markforged continuous carbon fiber and onyx materials within MSC’s Digimat materials modelling software, and the cooperation will soon extend to provide full-process simulation and part performance with Finite Element Analysis (FEA) within a common CAE environment.

Olivier Lietaer, Business Development Engineer for Additive Manufacturing at e- Xstream Engineering, part of MSC, said:“Markforged is a pioneer in the 3D printing space, and its continuous carbon fibre material is so strong, it’s replacing aluminium in factories across the globe. This shift in design and manufacturing requires new analysis capabilities that can validate customer designs with the same confidence as traditionally manufactured parts. Because it applies data specific to printing conditions, Digimat gives customers 100% confidence that their part designs can be 3D printed, making additive manufacturing accessible to applications that require rigorous testing. Together, Markforged and MSC enable customers to guarantee the performance of a part from its material properties through to final part strength and weight.”

A partnership driven by customer demand

Danfoss Power Solutions is a global industry leader in providing mobile hydraulics and a complete range of energy-efficient and intelligent hydraulic, electronic, and electrical solutions for the construction, agriculture, and other off-highway vehicle markets.

Jeff Herrin, Vice President Research & Development, Danfoss Power Solutions said:“We’ve been using Markforged metal and carbon fiber printers for more than a year now, and they’re invaluable. We invested mostly with tooling in mind, and it’s simplified and optimized our supply chain process for replacing fixtures at a much lower cost than machining. But we wanted to identify more applications for 3D printing and validate the performance of our parts before they’re printed. The company’s partnership with MSC will not only demonstrate that their composite parts can replace metal, but also help identify a part's top potential. Simulating the ideal weight, ideal cost savings, and ideal lead times with MSC will help us reduce our time and material usage so we can just print and deploy.”

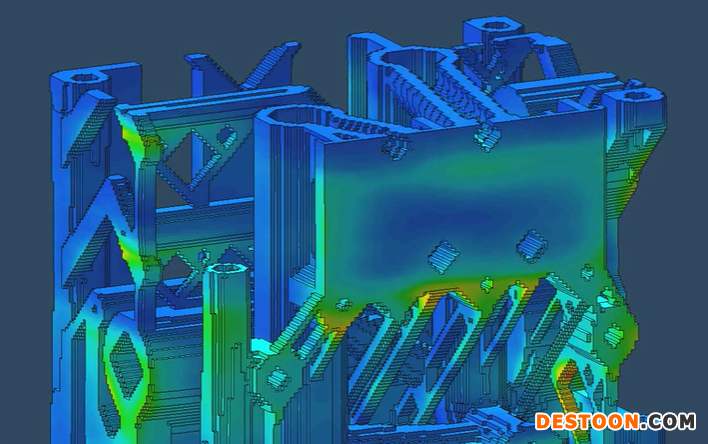

Recent advances in additive manufacturing, such as reinforced continuous fiber routing, are extending 3D printing use cases to structural parts that bear heavy loads. However, these structural applications often require pre-validation at the design level to ensure performance and safety requirements can be met. Danfoss printed a lifting bracket with Markforged that will lift cast housings on an assembly line. Given the suspended loads and the proximity of workers, validation is needed to ensure safe working conditions. With MSC and Markforged’s partnership, the simulation workflow has been validated on the bracket demo part and the failure location has been identified. The results show a significant safety margin that validates that the lifting bracket can be safely deployed in operations and furthermore offers an opportunity to reduce mass and cost.

Partnership features

Material Engineering – MSC and Markforged clients can access digital material cards that capture the mechanical and material properties of Markforged’s continuous fibers and chopped fiber-filled plastics.

Process Simulation – Clients will be able to model 3D printing within the MSC software. They will also be able to establish print calibration standards, ensure each machine is optimized for the part, and make sure each part is printed accurately the first time.

Part Performance – Customers will be able to connect the Markforged material and print information with FEA simulation from MSC. They can run simulations on proposed designs containing continuous fibers and printed thermoform plastics to predict the parts’ mechanical and structural performance.

Jon Reilly, VP of Product, Markforged said :“We’re thrilled to work with a leading provider of composite modeling and simulation software to provide this service to our customers. MSC’s best-in-class composites FEA will be critical in helping our customers identify the right design for their carbon fiber parts. 3D printing is transforming the factory floor, and with MSC as our partner, we can ensure all parts made with Markforged will perform at their peak potential.”(来源:MSCSOFTWARE)

Lu public network security: 37140202000173

Lu public network security: 37140202000173