“As nothing [is] available on the market for engine parts, we design and build our engine parts, pistons, rods crankshafts, and any other high-efficiency engine component,” states Extreme Tuners.

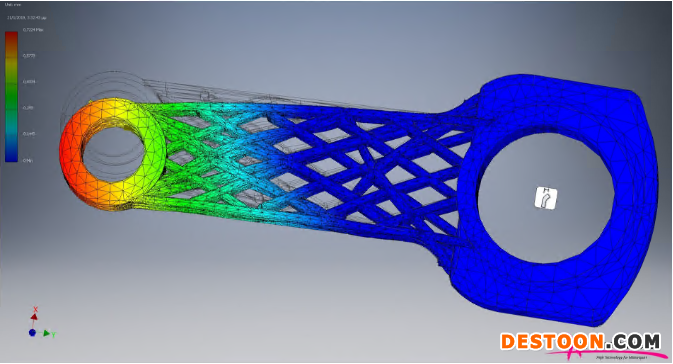

3D printed carbon composite connector rods

Carbon composite materials have been used in the automotive sector for cost-efficient tooling, as well as end-use car parts such as a 3D printed suspension upright and a 3D printed duct fitting. Extreme Tuners sought to leverage carbon composites to develop lighter, stronger and more heat resistant connector rods to be potentially used within carbon-ceramic brakes.

As internal combustion engine components, connector rods transfer motion from the piston to the crankshaft which then converts linear energy into rotational energy, enabling a vehicle’s wheels to drive the car forward. Connector rods are commonly made from aluminum alloy and can be heavy and stiff despite the component’s strength. This can hinder the car’s performance.

3D printed carbon composite connector rods on a tungsten divided billet crankshaft. Photo via Extreme Tuners.

Accelerating additive manufacturing in automotive parts

Using topology optimization, the 3D printed connector rods were designed and tested under the following criteria: 2916HP, 15,000 RPM, 37.2m/sec, and 57,363 pistons force. The company state that a bend of 0.5779mm on the small end was apparent, which is in an “acceptable limit comparing to our working time.”

The rods are also said to be less time-consuming to produce, and less likely to overheat. Extreme Tuners is now developing ceramic pistons and new ceramic rods to further address heating dissipation.(来源:3dprintingindustry)

Lu public network security: 37140202000173

Lu public network security: 37140202000173