Superfast aircraft, such as satellites, rockets, and jet aircraft, are often built of carbon fiber reinforced polymer composites that require shielding from heat to extend their lifespan. Existing heat shields are often thick compared to the base they protect, so the HPMI team set out to design and build a very thin skin-like shield that both protects the aircraft and helps support the structure.

Professor Richard Liang, director of HPMI, explained, “Right now, our flight systems are becoming more and more high-speed, even going into hypersonic systems, which are five times the speed of sound. When you have speeds that high, there’s more heat on a surface. Therefore, we need a much better thermal protection system.”

Buckypaper, sheets of carbon nanotubes (linked hexagons of carbon atoms in the shape of a cylinder) has been a focus of research at HPMI. The buckypaper offers exceptional ability to conduct heat and electricity, so it seemed to be a fit for the project. The engineering team soaked the buckypaper in a phenol resin compound to create a material that’s lightweight, flexible and durable enough to protect the superfast aircraft from the intense heat it deals within flight.

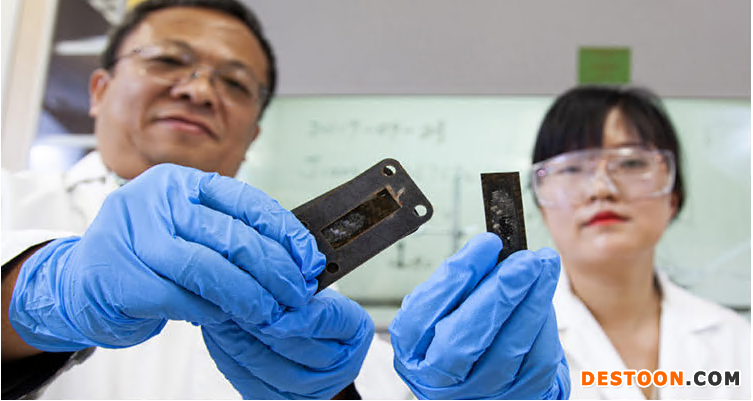

Heat shields of various thickness were tested, including tests of applying a flame to the samples to assure that the carbon fiber layer beneath was not damaged and bending the samples to assure they retained strength. The samples built with sheets of buckypaper were better than control samples at dispersing heat and they stayed strong and flexible. Of key importance to the aerospace industry, the lightweight test samples were less vulnerable to cracking at high temperatures compared to ceramics which are typically used in heat shields.

The United States Air Force Office of Scientific Research partially supported the project and the HPMI team hopes to continue to do research for the group in the future.(来源:compositesmanufacturing)

Lu public network security: 37140202000173

Lu public network security: 37140202000173